NIKIMAT

Amel Super Maramu 2000

|

Onan MDKAL Exhaust Elbow Replacement

As part of preventive maintenance, I decided to change the Onan Generator Exhaust Mixing Elbow. Spare parts needed:

Exhaust Mixing Elbow is part# 155-3261-02 (E086)

|

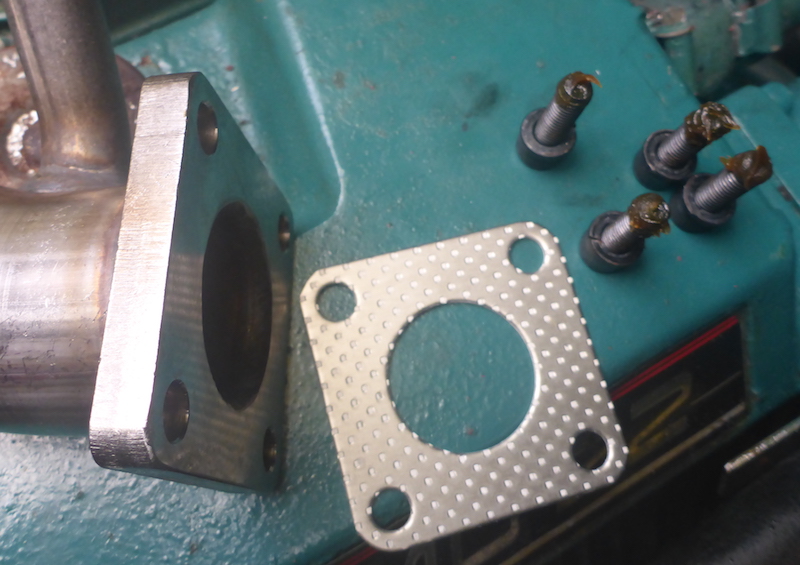

Exhaust Mixing Elbow and Exhaust gasket

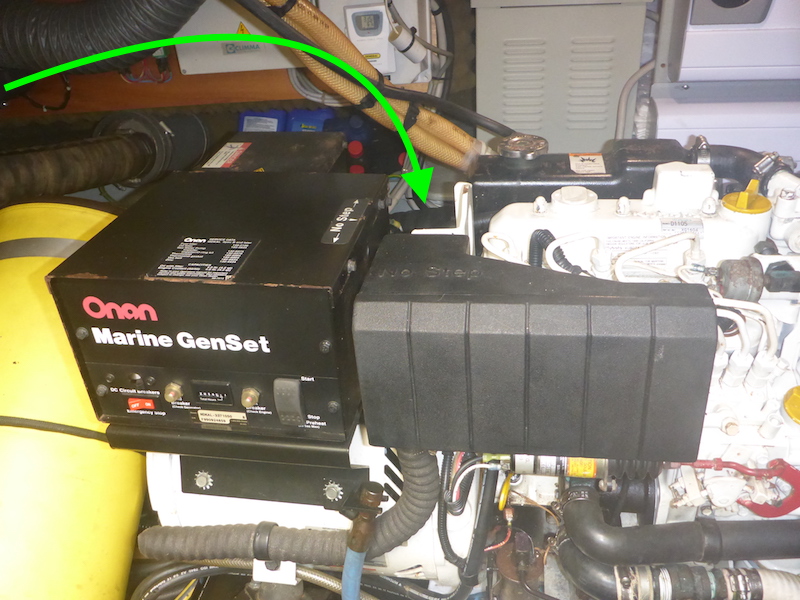

The green arrow shows the Exhaust Mixing Elbow

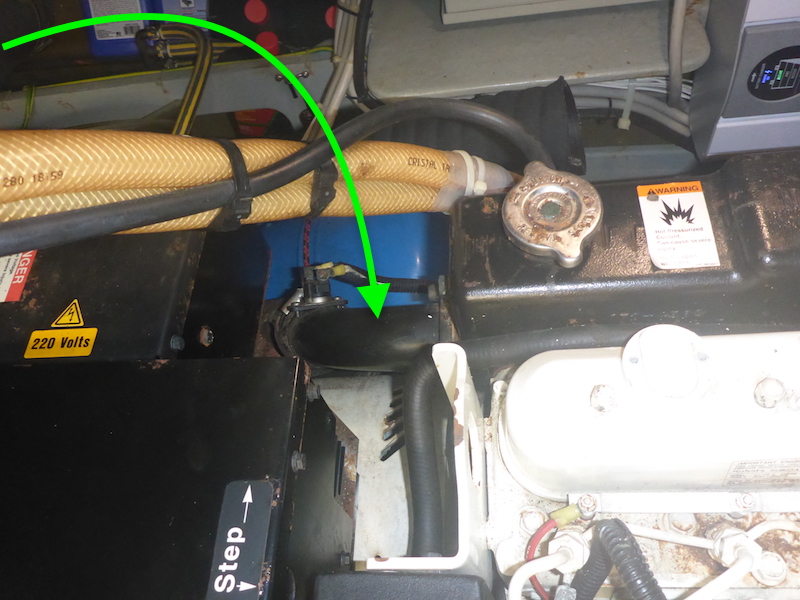

The green arrow shows the Exhaust Mixing Elbow (view from the top)

View from the Port side of the vessel

Removing the 2 bolt that hold the Exhaust temperature sensor

Without the sensor

Removing the 2 clamps on the Exhaust

Surprisingly the exhaust hose went out easily

Then removed the water hose and put the extra in a small cup

Using 6 mm Allen key I removed the bolt, was also surprisingly easy

All 4 bolt loosen

With the 4 bold remove the exhaust holds in place

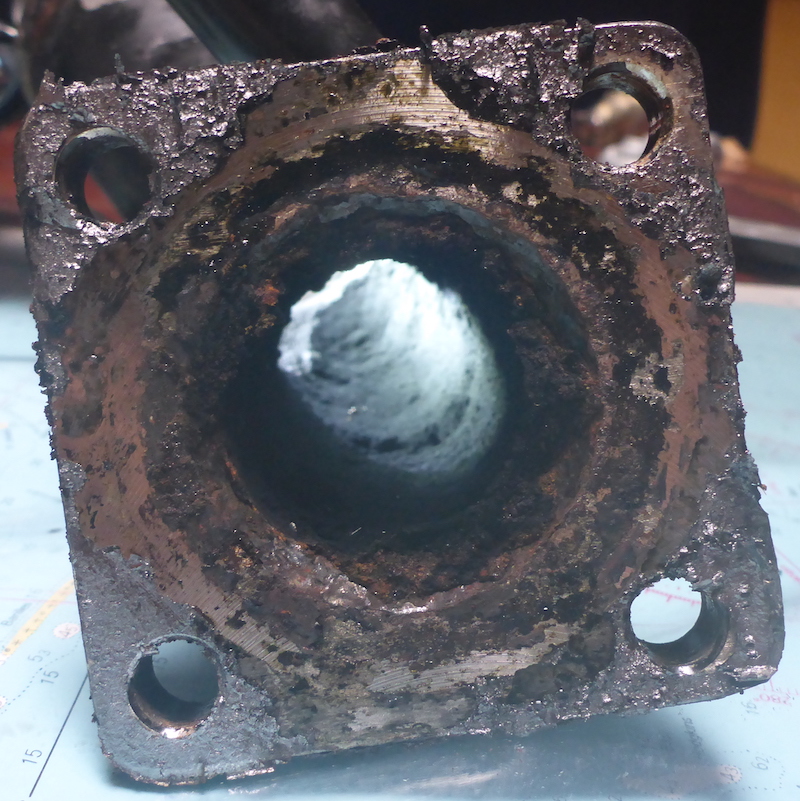

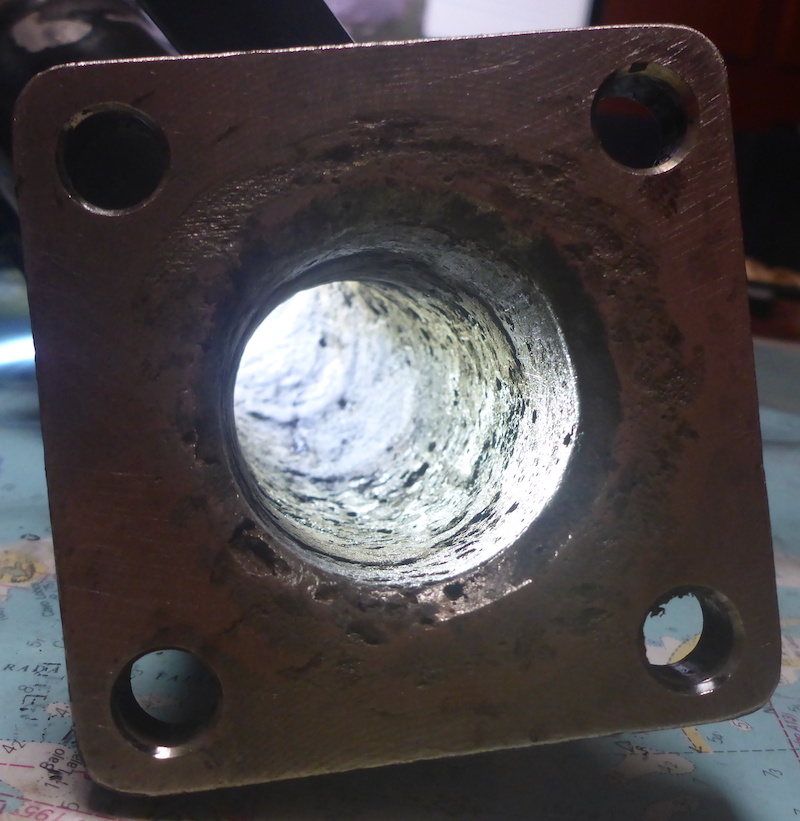

Lots of carbon built up, but not too bad

Can see the carbon built up

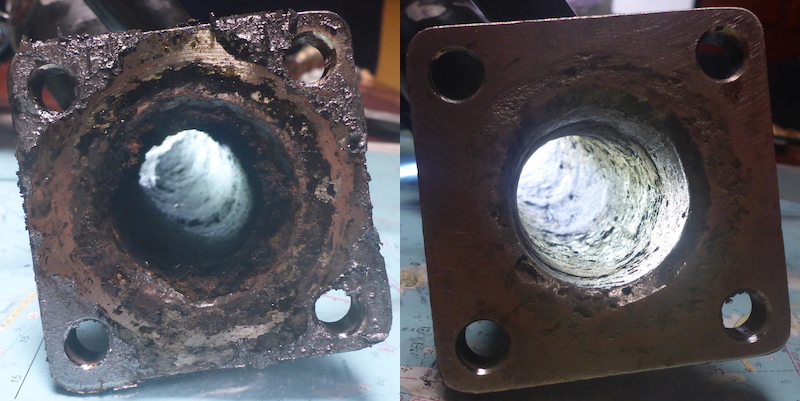

Comparison new and old

Putting light in

Now looking at the exhaust manifold build up

Preparing for cleaning

Used what I had

I also used a metalic brush and various grid of sand paper (from 60 to 100)

You can already see of the carbon build up in the plastic bag

Little rush on the bolt, using a brush to clean

Looking almost like new

Note from Bill Kinney SM160 Harmonie: the lock washer should be changed as they anneal and lose their spring.

Exhaust manifold looking better

Note all the carbon residue

Note all the carbon residue

Exhaust manifold Before/After

Putting Lanocote on the bolt before reassembly

Note from Bill Kinney SM160 Harmonie: Lanocote is not right for this application

Lanocote will not stand up to the temperatures of a diesel exhaust manifold.

For engine work Bill suggested to use a product called "Never-Seez" that is rated for higher temperatures.

There are lots of others that work, most of them are a suspension of powdered copper.

Note: James Maramu #220 SV Sueno added the Kennedy Space Center uses Phllips unflavoured Milk of Magnesia on the threads of fasteners that will be exposed to high temperatures to allow for easy removal. He has used this solution on exhaust systems of cars and boats for a long time and it really does work.

This is where I forgot to add a thin coat of Permatex High Temperature RTV as suggested by Gary

Note from Bill Kinney SM160 Harmonie: with a new gasket, and clean mating surfaces I wouldn't use RTV on this unless I had previous problems with leaks.

Note from Bill Rouse SM2K #387 BeBe: I would not use high temperature RTV on the new part, but would use it if I was refitting the old part because of the pitting in the metal.

bolt back and gently tight

Now re-attaching the exhaust hose with the 2 clamps

Note from Mark SM#275 Creampuff: should have changed the all hose screw clamps

Reconnected the water hose

Note from Mark SM#275 Creampuff: should have changed the all hose screw clamps

bolt back the exhaust temperature sensor

All back together

Using metallic brush and sand paper with grid ranging from 40 to 80 I cleaned as I could the Exhaust Mixing Elbow

With light to inspect

Original Exhaust Mixing Elbow Before/After